Often called a rotary screen, the trommel screen has become essential in waste management for separating recyclable and non-recyclable materials. From municipal waste facilities to recycling centres, it is widely used to efficiently sort plastics, metals, paper and organic matter. Its rotating drum separates materials by size, turning a once slow and labour-intensive task into a smooth, steady process.

Not only do trommel screen machines in India improve sorting accuracy, but they also reduce manual labour and allow facilities to handle larger volumes of waste quickly. Their simple design works well with both wet and dry materials, including mixed household and garden waste. Durable and easy to maintain, these machines are suitable for small local plants as well as large-scale waste centres.

Because of their efficiency and reliability, trommel screens remain a trusted choice in waste management, helping improve recycling rates and streamline material recovery.

What Is a Trommel Screen Machine?

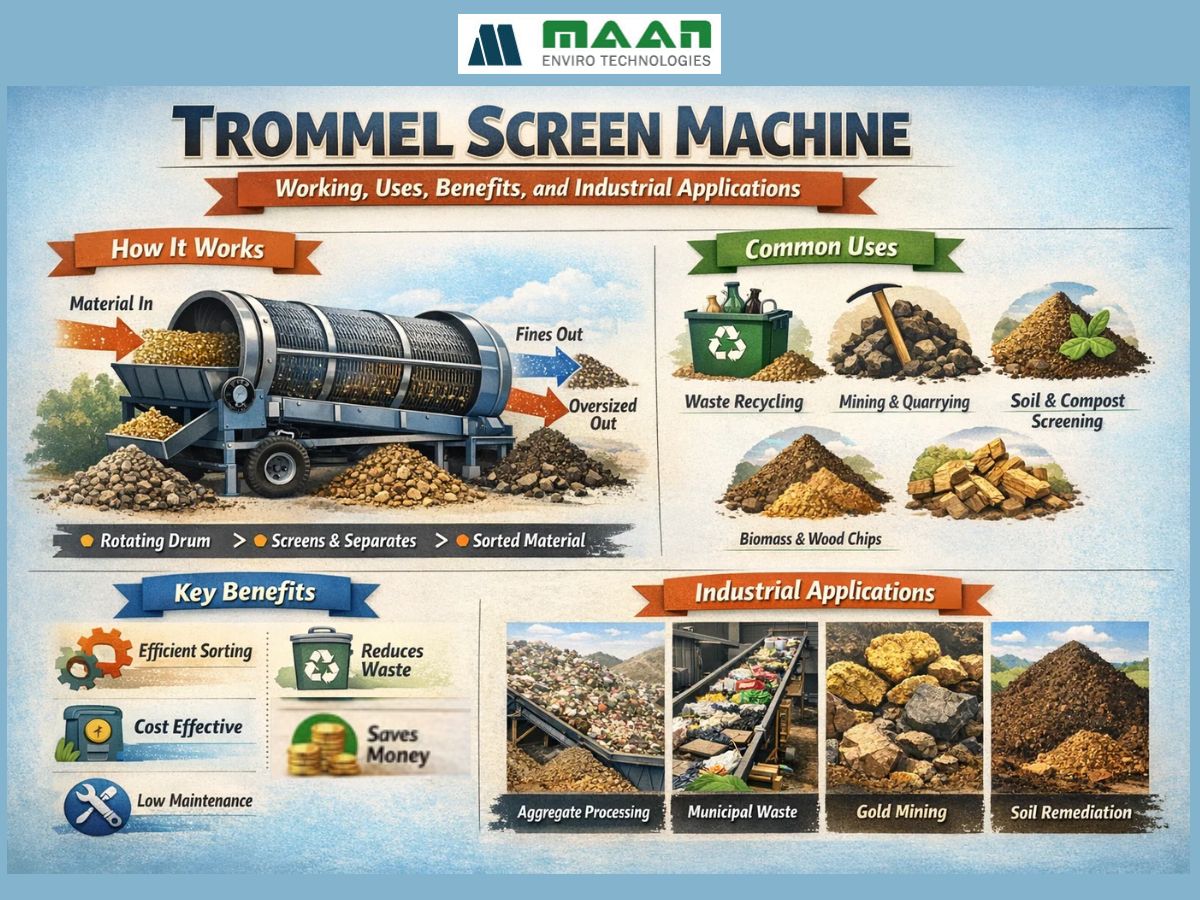

A trommel screen machine is a mechanical device used to separate materials based on size. Moreover, it consists of a cylindrical drum that rotates on a slight incline. Material is fed into the drum and as it turns, smaller particles fall through the perforated holes while larger pieces move to the end of the drum.

Trommel screening machines can handle different types of materials, including soil, compost, sand, gravel and waste. Since they are built for nonstop use, these machines can handle large amounts of material. Trommel screens are often equipped with brushes or scrapers to prevent clogging, ensuring consistent operation. When it comes to trommel screens vs ballistic separators for MSW applications, trommel screens are often preferred for handling mixed waste, as built-in brushes or scrapers help prevent clogging and support consistent, uninterrupted operation.

With a simple as well as efficient design, they deliver dependable performance while requiring little maintenance, suitable for both sorting and screening.

How a Trommel Screen Machine Works

By using a rotating drum, a trommel screen efficiently sorts waste, allowing materials of different sizes to be separated quickly and accurately. Here’s a step-by-step breakdown of how it works:

Step 1: Feeding the Waste

Waste is loaded into the drum, usually via a conveyor or hopper. This ensures a continuous as well as even flow of material, preparing it for proper sorting and connecting smoothly to the next stage.

Step 2: Rotating and Screening

Once the waste has been evenly fed into the drum, it starts rotating. Smaller particles fall through the perforated holes, while larger items continue toward the end. Because of the drum’s rotation, materials flow without stopping, stay unclogged and move directly from feeding to collection.

Step 3: Collecting Separated Material

Separated materials go into different bins or move on for further processing. Fine waste, like compostable material, falls through the holes, while larger recyclables as well as debris exit at the end, keeping the process continuous.

Key Benefits of Trommel Screen Machines

No matter the size or complexity of waste streams, trommel screen machines can handle sorting tasks with speed and consistency. Not only do they improve size-based separation, but they also help maintain a steady flow of material through the processing line. Built for continuous use, these machines reduce manual effort and improve overall processing efficiency.

Here are some of the major benefits of trommel screen machines.

Handles Mixed Waste Easily

One of the major benefits of a trommel screening machine is the fact that it can process uneven and mixed waste without frequent blockages. Its rotating drum allows different materials to move and separate smoothly during screening.

- Processes organic and inorganic waste together: With a trommel screening machine, food waste, plastics, paper, soil, and debris can be screened in a single flow without the need for pre-sorting.

- Reduces blockages from bulky items: The rotating drum of a trommel screening machine helps prevent jams caused by oversized or irregular waste pieces.

- Maintains steady separation: These machines separate waste reliably, no matter how the composition varies.

By handling mixed waste reliably, trommel screening machines support smooth operations and dependable material separation in waste processing facilities.

Works with Wet and Dry Waste

In addition to processing uneven and mixed waste without frequent blockages, trommel screen machines can also handle both wet as well as dry waste with ease. The rotating drum allows moist, sticky materials and dry waste to move smoothly through the screening process.

- Handles moisture-rich waste effectively: With a trommel screening machine, wet waste such as organic matter or damp soil is screened without clogging the openings.

- Screens dry materials consistently: Dry waste like plastics, paper, and light debris moves evenly through a trommel screening machine, maintaining stable separation.

- Prevents clogging and sticking: Trommel screening machines allow wet and sticky materials to pass through the drum without building up, ensuring continuous screening and reducing downtime caused by material sticking or blocking the openings.

This capability ensures that trommel screen machines in India deliver consistent performance as well as smooth operation, regardless of the type or moisture content of the waste.

High Throughput Capacity

With trommel screening machines, large volumes of waste can be processed continuously, making them ideal for facilities that handle heavy loads. Their rotating drum ensures steady material movement, allowing fast and efficient separation without frequent stoppages.

- Supports simultaneous multi-fraction separation: The machine’s large drum and perforation design enable it to separate several material sizes at once, increasing the overall throughput without additional passes.

- Maintains consistent output: Even under heavy loads, the machine continues to separate materials reliably, ensuring smooth operations throughout the day.

- Reduces processing time: With the ability to handle large quantities at once, trommel screening machines help facilities complete sorting tasks faster and more efficiently.

By handling large volumes of waste efficiently, trommel screening machines help facilities maintain steady operations and achieve higher material recovery without compromising separation quality.

Improves Material Recovery

Since trommel screening machines separate waste by size accurately, more recyclable and compostable materials can be recovered from mixed waste streams. Furthermore, this helps reduce the amount of waste sent to landfills while increasing the efficiency of recycling and composting operations.

- Recovers valuable recyclables: Plastics, metals and paper are sorted effectively, ensuring that more materials are redirected for reuse.

- Enhances compost quality: Organic waste is separated properly, resulting in better-quality compost for farming or landscaping.

- Reduces contamination: By keeping different material types apart, trommel screening machines minimise cross-contamination, improving the overall recovery rate of usable waste.

With improved separation as well as recovery, trommel screening machines help facilities maximise recyclable and compostable material recovery while reducing landfill waste and improving overall operational efficiency.

Uses of Trommel Screens in Waste Management

Whether you want to streamline waste sorting, separate materials by size or improve recycling and composting efficiency, trommel screening machines make handling large volumes of mixed waste faster and more reliable. They simplify sorting and help facilities manage different types of waste with ease.

- Organic Waste Sorting: Trommel screens efficiently separate organic and compostable waste, ensuring clean fractions that can be sent directly for composting or further processing.

- Recyclable Material Separation: These machines help recover recyclables such as plastics, metals as well as paper by separating them from mixed waste streams for reuse or recycling.

- Construction Debris Screening: Trommel screens can screen soil, sand and debris from construction as well as demolition waste, allowing usable materials to be recovered while removing unwanted bulk.

- Oversized Material Removal: They effectively remove oversized or bulky items from municipal solid waste, preventing blockages and ensuring smoother downstream processing.

- Refuse-Derived Fuel Preparation: Waste is divided by size in these machines, which improves the efficiency of preparing refuse-derived fuel.

- Labour and Time Efficiency: By automating sorting, trommel screens reduce manual labour requirements and speed up material recovery processes, improving overall operational efficiency.

By efficiently handling different types of waste and automating the separation process, trommel screening machines in India help facilities improve recovery rates, streamline operations and manage large volumes of waste with greater ease and reliability.

Industrial Applications of Trommel Screen Machines

From municipal solid waste processing to recycling operations, trommel screening machines can efficiently separate different types of waste. They help industries streamline sorting, recover valuable resources, and maintain smooth operations even with large volumes.

These machines are also used in composting facilities and construction sites to separate organic matter, soil and debris. Trommel screening machine’s versatility as well as reliability make them an essential part of modern material processing operations.

Municipal Solid Waste Processing

Trommel screening machines can be used in municipal solid waste plants to separate organic waste, recyclables and bulky materials efficiently. By sorting materials by size, they can help reduce landfill waste and improve the recovery of valuable resources.

Recycling Centres

With the help of trommel screening machines, recycling centres can sort plastics, metals, paper and other recoverable materials from mixed waste more efficiently. This can boost recovery rates, reduce manual labour and streamline overall recycling operations.

Construction and Demolition Sites

For handling waste at construction and demolition sites, trommel screening machines can sort soil, sand, gravel and debris efficiently. They can enable the recovery of reusable materials, reduce landfill disposal and make site cleanup more streamlined and manageable.

Composting Facilities

Trommel screening machines can also help separate organic waste from non-compostable materials effectively in composting facilities. They can enhance compost quality, streamline the processing workflow and produce a more uniform and usable end product.

Partner with Maan Enviro Technologies for a Cleaner Future

Maan Enviro Technologies provides reliable and customisable trommel screen machines to meet varied waste processing needs. From small-scale operations to large industrial facilities, Maan Enviro Technologies’ solutions help streamline waste processing, enhance material recovery and support efficient, sustainable operations.

Maan Enviro Technologies is a proud sales partner of M&J Recycling in India, offering pre- and fine shredders that process up to 200 tons per hour and reduce material size to 10 mm. These shredders work seamlessly with trommel screening machines, ensuring waste is properly prepared for efficient size-based separation.

- Customisable Drum Sizes: Select from different drum lengths as well as diameters to match specific operational requirements.

- Flexible Drive Mechanisms: Electric or hydraulic drives are available to match different facility requirements.

- Adjustable Screen Perforation: Select the ideal hole size for precise material separation.

- Varied Throughput Capacities: Machines are designed to handle different volumes efficiently.

- Durable: Built for long-term performance with minimal upkeep.

With Maan Enviro Technologies, facilities can achieve efficient, sustainable and reliable waste processing.

Frequently Asked Questions

What are the main benefits of using a trommel screen for waste management?

Trommel screens improve sorting accuracy, reduce manual labour, handle large volumes efficiently and require minimal maintenance. They are durable, energy-efficient and suitable for both small local plants and large municipal facilities.

Why choose a trommel screen over other waste sorting methods?

Trommel screens provide continuous size-based separation, reduce clogging and handle mixed materials effectively. They integrate easily with other waste processing equipment, making them reliable for large-scale municipal and commercial waste operations.

Can trommel screens handle wet or mixed waste?

Yes, trommel screens can handle both wet and dry waste. Furthermore, the rotating drum of the trommel screening machine keeps materials moving smoothly, preventing blockages and making it easy to separate mixed household, commercial or garden waste.

How customisable are trommel screens for waste processing?

Drum size, perforation type, and throughput capacity can be adjusted to match specific waste types and volumes. This flexibility ensures efficient sorting and optimal material recovery for different waste management needs.

How much waste can a trommel screen process in a day?

Trommel screens are designed for high-volume processing. Depending on drum size and machine capacity, they can handle several tons of municipal solid waste daily, making them suitable for both small local plants as well as large-scale facilities.

Summary

Trommel screen machines efficiently separate waste by size, improving recycling, composting and debris management. These machines can handle wet, dry and mixed materials while reducing manual labour. Widely used in waste processing facilities, construction sites and industrial plants, they enhance material recovery and streamline operations for sustainable waste management.